| |

1 Spring washers should be made of wire according to all-Union State Standard 11850-72 or another normative and technical documentation made of steel 65G, 70 and 3H13. It’s acceptable to make spring washers of bronze BrKMtsZ according to all-Union State Standard 18175-78 or other non-ferrous alloys. (Redraft, Alteration ¡í3)

2 Mass of steel washers and calculated elastic force from steel 65G are in the informative annex.

3 Steel spring washers should have hardness 41,5 - 49,5 HRC§ï (HRC 40-48), bronze ones at least 90 HRB. It’s acceptable to increase hardness up to 51,5 HRC§ï (HRC 50) for washers made of steel 70.

4 There should be no scales, burrs, flaws and corrosion on washer face. Track of inseparable scale is not a discarded sign. Defects which don’t influence on washers’ operational characteristics and don’t output dimensions for maximum deviation are acceptable.

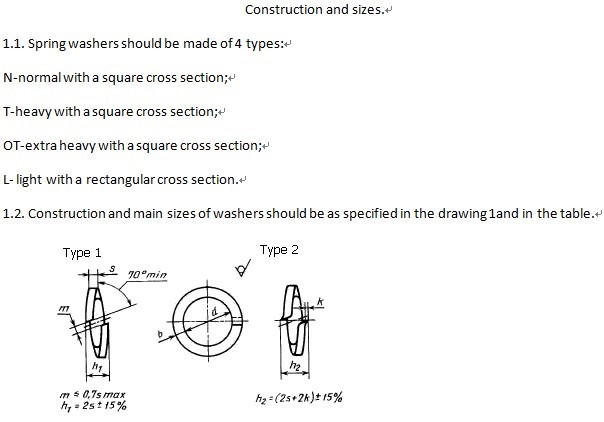

5 Washer’s end should have flat surface; shearing of metal, which don’t output dimensions m for maximum deviation, is not a discarded sign.

Edge formed by shear plane and washer supporting surface must be sharp.

6 Trapezoidal washer section within height s is not a discarded sign.

For the actual thickness is taken maximum size of heights.

7 (Excluded, Alteration ¡í3)

8 Washers should be made with covering or without it. Type of covering, their conventions and thickness - according to all-Union State Standard 1759.0-87. It’s acceptable to use other types of covering - according to all-Union State Standard 9.306-85. (Redraft, Alteration ¡í3). Please contact us for more.

|

|